In the dairy business, ultrasonic milk analyzers have become a technological marvel, providing quick and precise measurements of milk components. To assess the financial impact of this technology on dairy farms and processing facilities, a comprehensive cost-benefit analysis is necessary before making any investment decisions.

Expenses Related to Ultrasonic Milk Analyzers

- The analyzer constitutes a considerable initial financial commitment.

- It is essential to take into account the expenses related to installation, calibration, and ongoing maintenance.

- Continuous calibration and the utilization of reagents due to mishandling may lead to increased costs.

- Equipment failures can cause downtime, which can disrupt operations and result in repair costs.

Assessing Investment Return

It’s crucial to put a figure on the expenses and advantages of an ultrasonic milk analyzer in order to calculate ROI. Important points to think about are as follows:

- Determine the extra money that comes in from better milk quality and timely payment.

- Calculate how much labor and reagent costs will be cut, as well as any possible losses from poor build quality.

- Calculate the time savings and higher output capacity brought about by the quicker analyzers like LactoSure brand.

- Assess the information generated by the analyzer and its possible contribution to improve farm management and product development.

- Determine how long it will take to recover your initial investment through lower expenses and higher profits.

Factors to Take into Account for Dairy Farms and Processing Plants

- Due to greater potential cost reductions, larger farms producing more milk are more likely to benefit from the technology.

- The price of upgrading or replacing current testing apparatus needs to be taken into account.

- The right staff and software are needed to use the generated data effectively.

- Ultrasonic analyzer use may be required to ensure compliance with legislation and standards pertaining to milk quality.

Dairy farms and processing plants can decide whether to invest in ultrasonic milk analyzers by carefully weighing these factors and conducting a thorough cost-benefit analysis. According to current dairy standards, milk collection centers and BMCs should definitely install milk analyzers.For many operations, the investment can be justified despite the potentially high initial expenses because of the long-term benefits of better milk quality, enhanced efficiency, and financial returns.

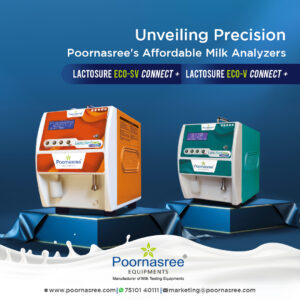

Boost Your Dairy Profits with LactoSure Ultrasonic Milk Analyzer

The LactoSure ultrasonic milk analyzer, developed by Poornasree Equipments, significantly contributes to improving the return on investment (ROI) for dairy farms and processing facilities.

The quick identification of quality issues by the LactoSure milk analyzer enables timely corrective measures, resulting in improved milk quality, fewer rejections, and higher milk prices. Equitable compensation for farmers, grounded in precise milk composition, fortifies the relationship between producers and processors. The data generated enables well-informed decisions regarding feed, breeding, and processing, thereby enhancing efficiency and reducing costs. Automation contributes to time and labor savings, while expedited analysis accelerates the processing and distribution of milk, ultimately improving cash flow.

To maximize the benefits of LactoSure milk analyzer, it is crucial to implement strong data management and analytical strategies, along with ensuring that personnel are adequately trained to utilize its functionalities effectively. Regular calibration and maintenance are imperative for achieving accurate results.

By adhering to these guidelines, dairy enterprises can maximize the capabilities of the LactoSure analyzer, leading to substantial enhancements in both profitability and sustainability.