-

Precision Meets Innovation

These cutting-edge tools provide farmers and dairy producers with valuable insights, leading to improved milk quality and increased productivity. By embracing innovation, the dairy industry can elevate its standards and meet the ever-growing demand for high-quality dairy products.

-

Revolutionize Your Dairy Analysis

Discover the speed and efficiency of Lactosure, the fastest ultrasonic milk analyzer. this cutting-edge device measures essential milk components, such as fat, protein, and lactose, with unmatched precision.

-

Unleash Efficiency

The compact and portable design makes it perfect for on-site testing, while the user-friendly interface ensures seamless operation. Experience the power of Lactosure and revolutionize your dairy analysis process, saving time and resources without compromising quality.

-

Precision Meets Innovation

These cutting-edge tools provide farmers and dairy producers with valuable insights, leading to improved milk quality and increased productivity. By embracing innovation, the dairy industry can elevate its standards and meet the ever-growing demand for high-quality dairy products.

-

Revolutionize Your Dairy Analysis

Discover the speed and efficiency of Lactosure, the fastest ultrasonic milk analyzer. this cutting-edge device measures essential milk components, such as fat, protein, and lactose, with unmatched precision.

-

Precision Meets Innovation

The compact and portable design makes it perfect for on-site testing, while the user-friendly interface ensures seamless operation. Experience the power of LactoSure and revolutionize your dairy analysis process, saving time and resources without compromising quality.

-

Revolutionize your Dairy Analysis

Discover the speed and efficiency of LactoSure, the fastest ultrasonic milk analyzer. this cutting-edge device measures essential milk components, such as fat, protein, and lactose, with unmatched precision.

-

Unleashing Technology

These cutting-edge tools provide farmers and dairy producers with valuable insights, leading to improved milk quality and increased productivity. By embracing innovation, the dairy industry can elevate its standards and meet the ever-growing demand for high-quality dairy products.

-

Precision Meets Innovation

These cutting-edge tools provide farmers and dairy producers with valuable insights, leading to improved milk quality and increased productivity. By embracing innovation, the dairy industry can elevate its standards and meet the ever-growing demand for high-quality dairy products.

-

Unleashing Technology

These cutting-edge tools provide farmers and dairy producers with valuable insights, leading to improved milk quality and increased productivity. By embracing innovation, the dairy industry can elevate its standards and meet the ever-growing demand for high-quality dairy products.

Who We Are

Poornasree is a leading brand in the milk testing equipment industry, offering an extensive range of cutting-edge products designed to cater to the needs of dairy farmers and processors worldwide. Established in 2011, the brand is known for its high-quality products, innovative solutions, and exceptional customer service. Poornasree’s product range includes milk analyzers, milk stirrers, display units, and data processing devices. The brand’s commitment to quality, innovation, and customer satisfaction has earned it a loyal and growing customer base.

Our Innovations

We offer advanced milk analyzer equipment that ensures accurate and efficient analysis of milk quality. Our state-of-the-art devices are designed to provide precise measurements of various parameters, such as Fat, SNF, CLR, Protein, Lactose, Added Salkt, added water & Temperature. The equipment is user-friendly, easy to maintain, and built to withstand rigorous usage.

Latest updates at Poornasree

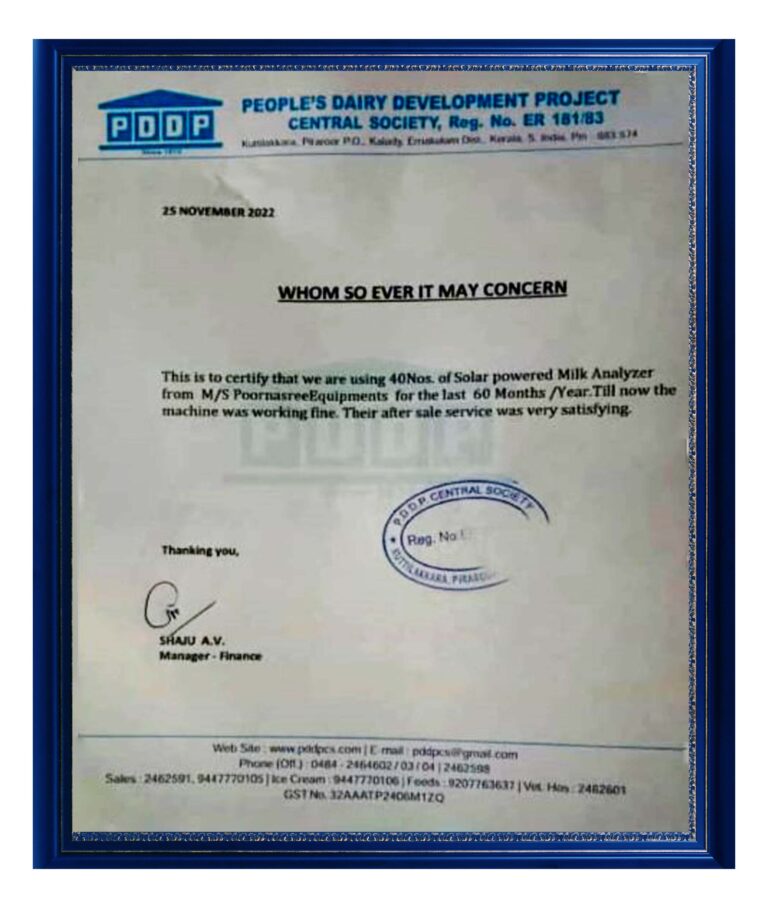

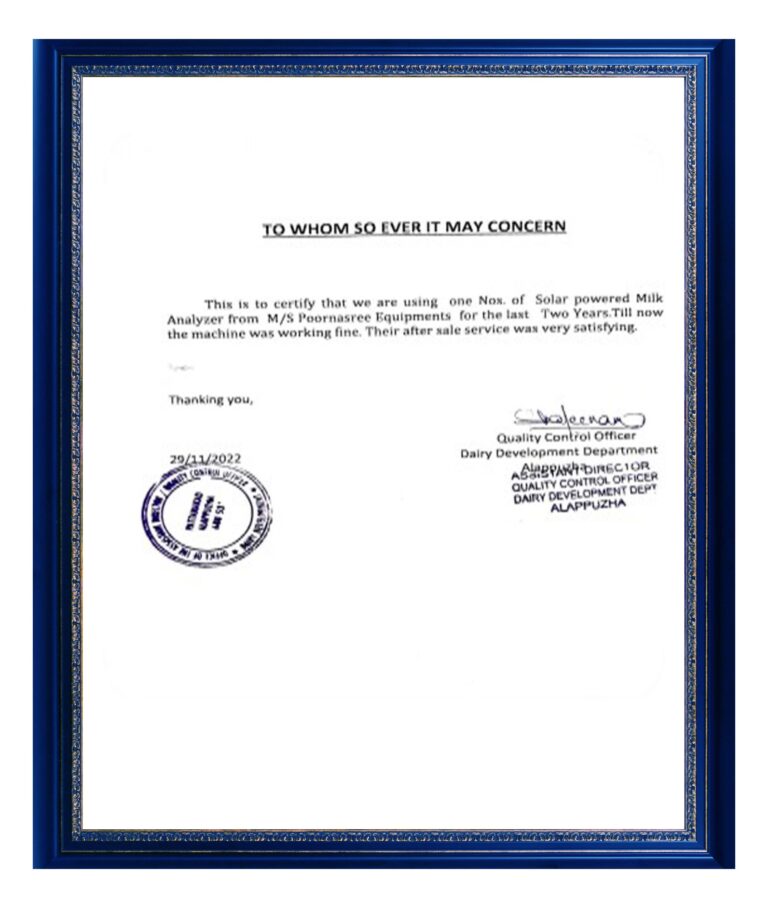

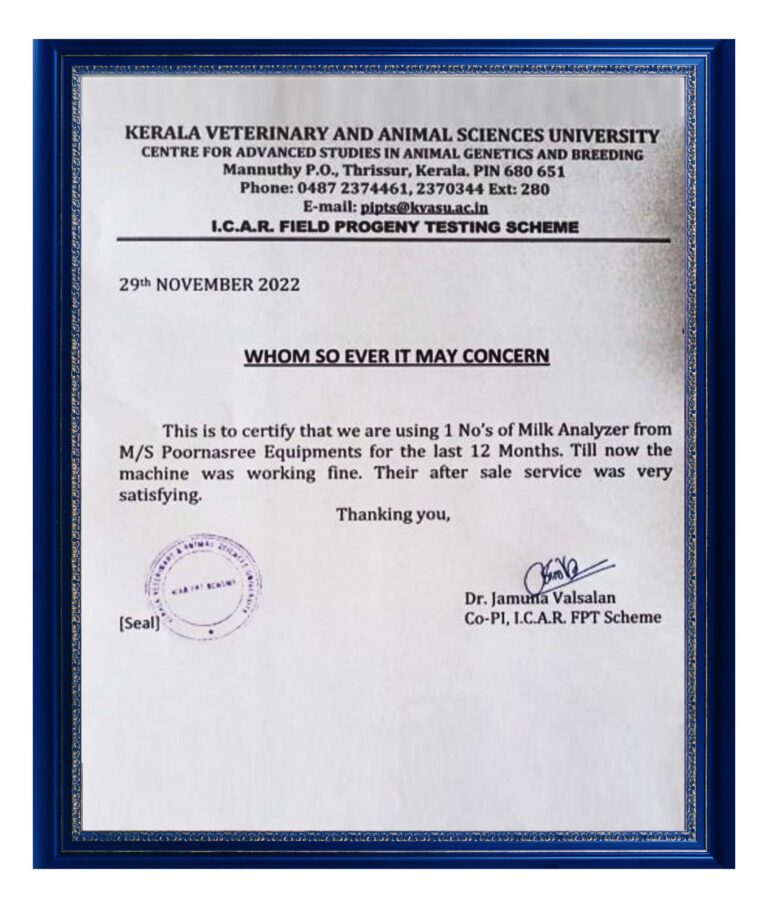

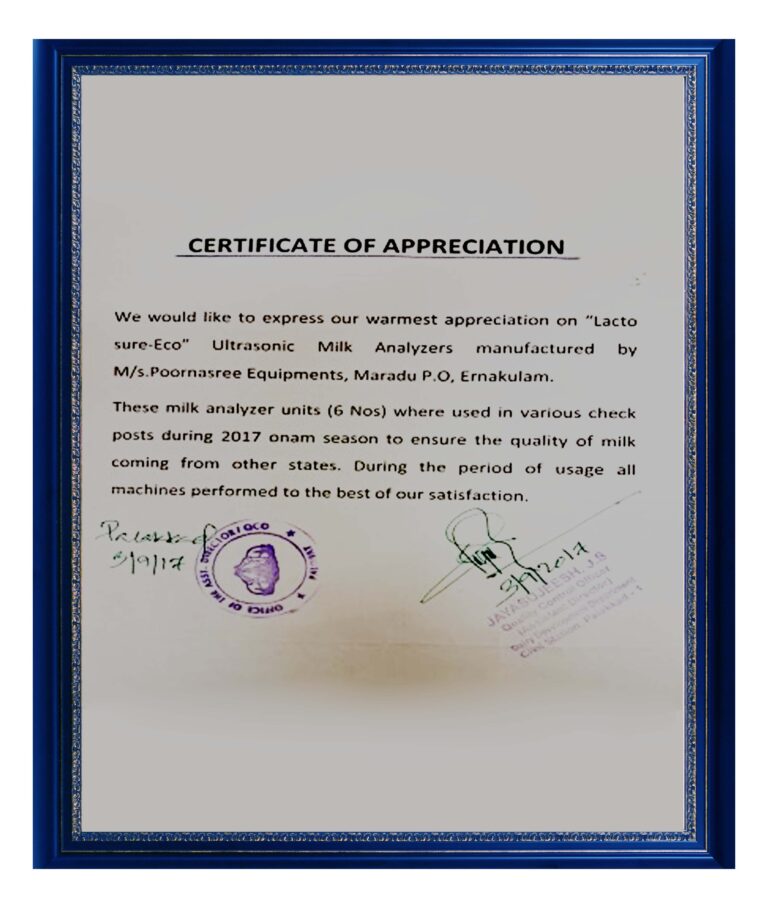

What our client says